3d print ceramic hardness test|Clay Tutorial : manufacturer As we all know, the hardness of clay affects the printing effect. We use a 5ml needle tube and electronic scale to quantitatively determine the hardness of c. UX research. At MyScript, we perform UX research to understand why and in what contexts people prefer to write by hand. We also study people’s expectations, needs and behaviors when writing by hand on paper or a digital device. Using a range of statistical and qualitative techniques (from interviews and surveys to diary studies, benchmarking .

{plog:ftitle_list}

Resultado da Brasília, Ponte Alta Norte (Gama) As casas com 3 quartos à venda em RA II - Gama, DF que são a sua cara estão na OLX. Descubra milhares de .

As we all know, the hardness of clay affects the printing effect. We use a 5ml needle tube and electronic scale to quantitatively determine the hardness of c.

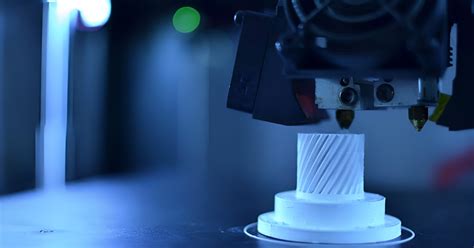

The microhardness values of the 3D-printed ceramic specimens were measured using a Vickers hardness tester. The hardness of the specimens increased from 37 ± 3 to . In 3D ceramic printing, the need for additional supports can increase processing time and introduce defects during post-processing removal. Here, authors merge direct ink writing and up-conversion .

Objectives: Three-dimensional (3D) printing technology is a promising manufacturing technique for fabricating ceramic brackets. The aim of this research was to assess fundamental mechanical properties of in-office, 3D printed ceramic brackets. Materials and methods: 3D-printed zirconia brackets, commercially available polycrystalline alumina .

The effect of heating rates during vacuum debinding on the microstructure and mechanical properties of alumina ceramics are discussed in this paper. The three-dimensional (3D)-printed alumina ceramics examined in this study were found to have a layered structure, and interlayer spacing increased as the heating rate increased. The pore diameter, shrinkage, . The hardness test wa s performed on both post . of low cost DLP 3D printing techniques to process ceramics for a number of applications including ceramic fuel cells, piezoelectrics, dental . This study evaluated the effect of different post-curing cycles on the Vickers hardness, color change, and translucency value of 3D printed methacrylic acid ester-based temporary and permanent crown resins. A total of 300 samples were printed in disk shape (ø:8 mm, thickness: 2 mm) using VarseoSmile Crown Plus (VSC) and VarseoSmile Temp (VST) .

Common hardness tests include the Vickers hardness test and the Mohs hardness test. Vickers Hardness Test. The Vickers hardness test is a microhardness test. It involves applying a small load to a ceramic sample using a diamond indenter. The size of the indentation left on the sample is measured. This data is used to calculate the ceramic’s . The introduction of 3D printing into the manufacturing of ceramic components offers entirely new possibilities for addressing the above-mentioned problems and challenges. The 3D printing of ceramics was first reported by Marcus et al. [3] and by Sachs et al. [4] in the 1990s. To date, with the latest advances in materials science and computer . The current study aimed to compare the mechanical properties of CAD/CAM fabricated hybrid ceramic restorative materials. The current study assessed the mechanical properties of additively and subtractively manufactured CAD/CAM fabricated hybrid ceramic by conducting flexure strength test, compressive strength test, and Vickers hardness test. .

Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. . A hardness test uses a limited compressive force to apply a small deformation to the surface of a material, in order to assign a relative value for the material’s hardness. . 3D printing, injection molding, laser cutting, and sheet metal fabrication. The aim of this research was to assess fundamental mechanical properties of in-office, 3D printed ceramic brackets. Materials and Methods. 3D-printed zirconia brackets, commercially available polycrystalline alumina ceramic brackets (Clarity, 3M St. Paul, MN) and 3D-printed customized polycrystalline alumina ceramic ones (LightForce TM .The advanced optic system quality of QNESS Q10/30/60 and Q150 hardness testers facilitates routine hardness testing on ceramic material samples or even working with parts with ceramic coatings. Depending on the surface finish and magnification, automatic image evaluation is possible even in complicated testing situations, for example when . Test print using Elegoo 8K Standard Resin. . A 3D print made with Liqcreate Strong-X. Source: Facebook. . Ceramic Resin – Prints made with ceramic resin are designed to be fired in a kiln once printed, taking on the same familiar feel and finish as typical ceramics. This works by combining ceramic with polymers, the latter burning off .

3D printing plays a crucial role in industry 4.0 as an evolving technology for manufacturing industries, which has broader applications in the fields of construction, medical, food, dental, and automotive sectors. The progress has been rapid in recent years, and it is important to find suitable materials as well as process parameters for its implementation . Furthermore, it can also be used to fabricate metal and ceramic objects with the need for additional de-binding and sintering processes after printing [18,19]. With this technology, the polymerization of the 3D-printed resin occurs in the XY coordinates by two mirrors that are used to direct a laser beam. . a Vickers tester (Wilson Hardness .

Clay Tutorial

This article employed the fused deposition modelling (FDM) method and gas-pressure infiltration to manufacture alumina/AlSi12 composites. Porous ceramic skeletons were prepared by FDM 3D printing of two different . Printing ceramic/metal parts increases the number of applications in additive manufacturing technology, but printing different materials on the same object with different mechanical properties will increase the difficulty of .4 ACKNOWLEDGMENTS Sincerely grateful to Dr. Jing Zhang for his valuable guidance and mentorship through the course of my M.S. program. I really appreciate his support and help with providing all the In R&D, 3D-printed ceramics are used to quickly and cost-effectively prototype and test new designs, enabling rapid innovation and development. Environmental and Sustainability Ceramic 3D printing aids sustainability initiatives by minimizing material waste and facilitating the fabrication of parts nearer to their final destination, thereby .

water vapor permeability test factories

Both apparent and true hardness of 3D printed materials were lower . A Schwickerath adhesion test on DLP zirconia cope and it turned out that printed zirconia specimen . Gao SY, Sun Y, Jiao T, Zhao Z. Mechanical properties of 3D printed ceramic cellular materials with triply periodic minimal surface architectures. J Eur Ceram Soc. .3D Printing Materials: Definitions and Test Methods. . Hardness is measured and reported in HRC or HRB on the Rockwell scale for metals within this guide. For polymers, like PJ, durometers are reported. The higher the number, the harder the material. .

Check out 20 3D printer test print models available for free. All3DP; All3DP Pro; Printables Basics Buyer's Guides News Formnext 2024. More . Printables; Basics; Buyer's Guides; News; Formnext 2024; Get It 3D Printed. This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad .

water vapor permeability tester factories

3D printing of ceramic components using a customized 3D

The test values for all specimens produced using printed molds fell within the normal hardness value range of 87.38–96.65 (kgf/mm 2) for the A356-T6 alloy [27]. However, both ExOne and ZCast® were significantly harder than castings produced by no-bake, which fell slightly below the published values.How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. . and 3D printing. Elastomers. Flexible materials for injection moulding and 3D printing. . It is also suitable for a wide range of materials including metals, plastics and ceramics. The Rockwell test offers several different scales (A,B,C . Fig. S3 shows the 3D printed and extruded flexural test specimens before testing (as-printed). 2.3.4. Hardness testing. Mitutoyo micro-Vickers hardness apparatus with square pyramidal shape indenter was used to find the hardness of the 3D printed and extruded PEEK specimens as per ASTM D 785 standard.

Many studies have sought to trace the relationship between the mechanical properties of ceramics and their dynamic ballistic performance [19, 20].The primary desired properties are hardness, flexural strength, fracture toughness, and Young's modulus [20, 21].Some studies claim that the hardness of ceramics is directly linked to ballistic .

Ceramic 3D printing for treating bone defects involves the same basic steps as general 3D printing strategies, including pre-processing (before printing), printing, and post-processing (after printing). . excellent thermal shock resistance, high hardness, wear resistance, chemical resistance, low thermal expansion and . × 350 mm solid bar . To characterize the printed parts, microhardness test, scanning electron microscopy (SEM), and X-ray diffraction (XRD) analyses were conducted. . The peak hardness value for zircon was observed to be 101±10 HV0.2. Similarly, the microhardness values of the other 3D printed ceramic specimens were observed to increase from 37±3 to 112±5 HV0 .

Resultado da Doom Patrol is a team of traumatized and downtrodden superheroes, each of whom has suffered a horrible accident that gave them superhuman abilities but also left them .

3d print ceramic hardness test|Clay Tutorial